Ptfe oil seal material

Itaflon oil seal material introduction

- Itaflon oil seal material introduction

Itron offers Hyperflon® Hyperion series filled modified PTFE for oil seals. Yi De long oil seal filled modified PTFE material performance is excellent, can be used in the vast majority of chemical fluids, solvents, and hydraulic oil, lubricating oil, its swelling is very small so can play a long-term sealing performance, provide the full condition of static or dynamic (reciprocating or rotating motion) oil seal seal modified PTFE material, the use of temperature range from refrigerant to 300℃, The pressure per unit area can reach 700kg, and the moving speed is as high as 20m/s.

- Itaflon oil seal material advantage

- Low friction coefficient

- Low thermal expansion coefficient.

- Excellent rebound rate

- Long reciprocating and rotating life under high pressure

Please contact Itron Sales for detailed application conditions corresponding to Hyperflon ® series products, or request a sample.

Application Details

Oil seal’s PTFE compound solution

Ptfe oil seal material solution

Jiashan Yidelong Fluorine Technology Co., LTD

Jiashan Itaflon Fluoro Technology Co., Ltd.

Italy Edron Co., LTD

ITAFLON S.r.l.

Yidelong oil seal material introduction

- Yidelong oil seal material introduction

Itron offers Hyperflon® Hyperion series filled modified PTFE for oil seals. Yi De long oil seal filled modified PTFE material performance is excellent, can be used in the vast majority of chemical fluids, solvents, and hydraulic oil, lubricating oil, its swelling is very small so can play a long-term sealing performance, provide the full condition of static or dynamic (reciprocating or rotating motion) oil seal seal modified PTFE material, the use of temperature range from refrigerant to 300℃, The pressure per unit area can reach 700kg, and the moving speed is as high as 20m/s.

- Yidelong oil seal material advantage

- Low friction coefficient

- Low thermal expansion coefficient.

- Excellent rebound rate

- Long reciprocating and rotating life under high pressure

Please contact Itron Sales for detailed application conditions corresponding to Hyperflon ® series products, or request a sample.

Scan add public account to learn more

Oil seal material selection guide - material specific formula correspondence table

- Hyperflon® SPTFE White PTFE Pure

- Hyperflon® MPTFE White PTFEG Modified Pure

- Hyperflon® UPTFE White PTFEG Supermodified Pure Material

- Hyperflon® G1 Black PTFE+ Glass Fiber/Graphite mix

- Hyperflon® G3 White PTFE+ Glass fiber boron nitride mixture

- Hyperflon® G Gray PTFE+ Glass fiber molybdenum disulfide mixture

- Hyperflon® CM2 Black PTFE+ carbon fiber molybdenum disulfide mixture

- Hyperflon® B Beige PTFE+ Polyphenyl ester

- Hyperflon® A yellow PTFE+ polyimide

- Hyperflon®K White PTFE+ polyether ether ketone

- Hyperflon® F3 Gray PTFE+ polyphenylene sulfide

- Hyperflon® PCM Gray PTFE+ polyphenylene sulfide mixture

Different formulations are selected according to different working conditions

For more stringent conditions, please consult the sales representative of Itron

Guide for oil seal material selection - Material properties correspondence Table

Oil Seal Series PTFE Composites - Mechanical Properties (ASTM D4894)

| Model |

SPTFE |

MPTFE |

UPTFE |

G1 |

G3 |

G |

CM1 |

B |

A |

K |

F3 |

PCM |

| Color | white | white | white | black | white | grey | black | beige |

yellow |

white | grey | grey |

|

Specific gravity (g/cm³) |

2.134 |

2.145 |

2.151 |

2.128 |

2.146 |

2.234 |

2.032 |

1.910 |

1.869 |

1.899 |

1.874 |

1.887 |

|

Tensile strength(mpa) |

36.83 |

33.99 |

35.1 |

20.71 |

20.67 |

25.74 |

22.87 |

22.82 |

23.68 |

24.45 |

22.63 |

16.26 |

|

Elongation at break(%) |

420.80 |

488.03 |

505.4 |

376.99 |

411.30 |

381.52 |

353.24 |

375.31 |

318.59 |

290.82 |

347.00 |

311.50 |

|

Shore hardness(Mpa) |

58 |

58 |

58 |

61 |

59 |

60 |

60 |

61 |

61 |

62 |

60 |

61 |

|

Shrinkage rate(%) |

2.60 |

2.92 |

4.16 |

1.79 |

2.27 |

1.93 |

1.33 |

2.50 |

3.07 |

3.30 |

3.39 |

2.99 |

| Coefficient of friction |

- |

- |

- |

0.187 |

0.204 |

0.193 |

0.097 |

0.166 |

0.120 |

0.152 |

0.145 |

0.179 |

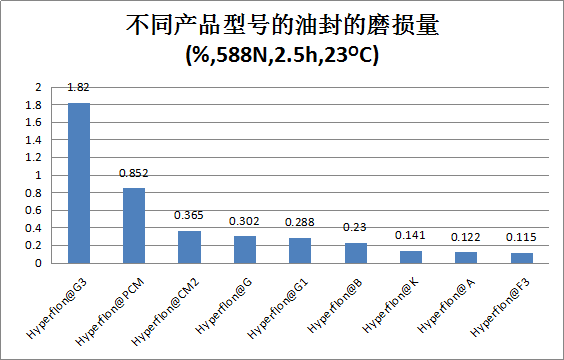

Oil Seal series PTFE composites - Wear resistance

Oil seal series PTFE composites - Pressure resistance

Oil seal material selection guide - Material type correspondence table

| Product model |

Seal parameter |

|||||

| function |

Axial diameter inch (mm) |

Pressure (Mpa) | Temperature (℃) | Surface velocity (m/s) | Spring type | |

|

Hypeflon®U/S/MPTFE |

It is widely used in some cast iron seat holes with high metal strength, small cold and hot deformation, and better processing size control. |

3.000 to 20.000 (76.2 to 508.0) |

There is no | -85 º C to 204 º C |

5.1 |

spring-free |

|

Hypeflon®G,G1 |

PTFE split seal Low-speed application Excellent resistance to chemical corrosion Cover plate is required for installation |

3.000 to 20.000 (76.2 to 508.0) |

There is no |

-85 º C to 204 º C |

5.1 |

Carbon steel Clamping spring |

|

Hypeflon®CM2 |

Prefabricated design Heavy metal skeleton Low-speed application Strong resistance to chemical corrosion |

0.437 to 20.000 (11.1 To 508.0) in max seal O.D |

To 7 psi (0.4 bar) |

-85 º C to 204 º C |

10.2 |

Carbon steel clamp Tight spring |

|

Hypeflon®A,B,K,F3 |

Special material (J type), chemical resistance, heat resistance, low friction | Ditto | There is no |

-50 ~ +220 |

10.2 |

Carbon steel clamp Tight spring |

|

Hypeflon®G3 |

Comply with food hygiene Act (for revolving use) | Ditto | There is no |

-50 ~ +220 |

10.2 |

Carbon steel clamp Tight spring |

Guide for oil seal material selection - Material working condition table

| Working medium | Medium-low speed | High speed | Normal pressure | High pressure | Non-rotational motion |

Rotational motion |

| Lubricating oil, pump oil, petroleum | other |

|

other |

|

|

other |

| Lubricating oil, pump oil, petroleum |

|

|

|

|

|

|

| Lubricating oil, pump oil, petroleum |

|

Hypeflon®A |

|

Hypeflon®A |

Hypeflon® UPTFE |

|

| Lubricating oil, pump oil, petroleum |

|

Hypeflon®PCM |

|

|

Hypeflon® MPTFE |

|

| Lubricating oil, pump oil, petroleum |

|

|

|

|

Hypeflon®SPTFE |

|

| Lubricating oil, pump oil, petroleum |

|

Hypeflon®F3 |

|

Hypeflon®F3 |

|

|

Guide for storage and use of oil seal materials

- In the case of powder, the vibration or high temperature powder may clump during transportation. Cool the material before use and filter it with a screen, or crush it with a looser/crusher before normal use.

- Granulated material will not produce clumping, it is recommended to use stainless steel spoon to board.

- The recommended storage temperature is 20-25 ° C and the humidity is 25-55%.

- If the incoming material is not used up, it is necessary to tighten the double plastic bag with cable ties and change the lid of the bucket to avoid moisture absorption or contamination of the material.

- In the right storage environment, materials can be almost timeless and will not expire.

- During the production process, it is recommended that workers wear sufficient labor protection products (such as gloves, masks, etc.). For example, compressed air may contact relevant molds or tools, and it is recommended that compressed air pass through oil and water filtration devices.

Note: The above data in this specification is accurate and reliable, but does not imply that Itaflon assumes any warranty or liability. The technical data sheet does not exempt the customer from quality testing the suitability of the product through its own quality control procedures.

|

Jiashan Yidelong Fluorine Technology Co., LTD Jiashan Itaflon Fluoro Technology Co., Ltd. 9 Songhai Road, Jiashan County, Jiaxing City, Zhejiang Province, China No.9 Songhai road,Jiashan county,Jiaxing city,Zhejiang province +86 0573 84892086 |

Italy Edron Co., LTD ITAFLON S.r.l. 18, Zone A, SAO Paolo Diagon, Bergamo, Italy Via A. Volta, 18 24060 San Paolo D’Argon (BG) Italy +39 030 3663500 |

|

|

|

Related Applications

undefined