valve seat

Jiashan Itaflon Fluoropolymer Technology Co., Ltd. provides Hyperfloat for valve seats ® Hyperion series filled modified PTFE materials. Itaflon filled modified PTFE material has excellent performance, effectively solving the rebound problem of valve seat pressure. It can be applied to various high-temperature corrosive chemical fluids and solvents. Its low swelling ability can maintain sealing performance for a long time, and the temperature range can be from refrigerant to 300 ℃. The pressure per unit area can reach 700kg, and the movement speed can reach up to 20m/s.

- Advantages of Itaflon Valve Seat Material

- Low friction coefficient

- Low coefficient of thermal expansion

- Excellent resilience

- Excellent creep resistance under high pressure

Application Details

Valve seat’s PTFE Compound Solution

Jiashan Itaflon Fluoropolymer Technology Co., Ltd.

ITAFLON S.r.l.

- Introduction to Materials for Yidelong Valve Seat

Jiashan Itaflon Fluoropolymer Technology Co., Ltd.provides Hyperfloat for valve seats ® Hyperion series filled modified PTFE materials. Itaflon filled modified PTFE material has excellent performance, effectively solving the rebound problem of valve seat pressure. It can be applied to various high-temperature corrosive chemical fluids and solvents. Its low swelling ability can maintain sealing performance for a long time, and the temperature range can be from refrigerant to 300 ℃. The pressure per unit area can reach 700kg, and the movement speed can reach up to 20m/s.

- Advantages of Itaflon Valve Seat Material

- Low friction coefficient

- Low coefficient of thermal expansion

- Excellent resilience

- Excellent creep resistance under high pressure

Please contact Itaflon's sales to learn about the Hyperflon Hyperion corresponding to the detailed application conditions ® Series products, or request samples.

Scan to add a official account to learn more

|

Valve Seat Material Selection Guide - Material Specific Formula Corresponding Table

Choose different formulas based on different operating conditions For more demanding working conditions, please consult with Itaflon's sales representative

Valve Seat Material Selection Guide - Material Performance Correspondence Table PTFE composite material for valve seat series - mechanical properties(ASTM D4894)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

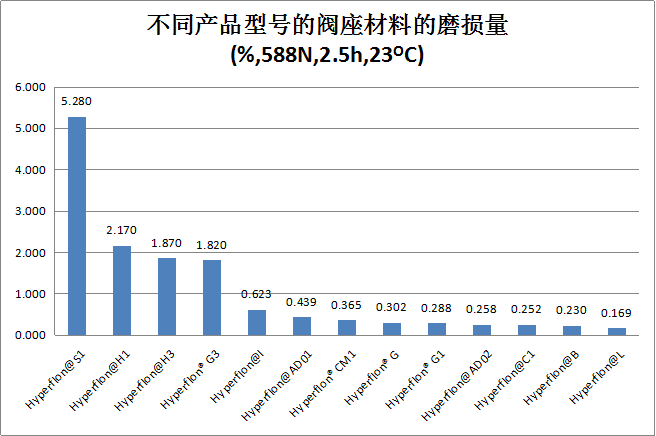

Valve seat series PTFE composite material - wear resistance

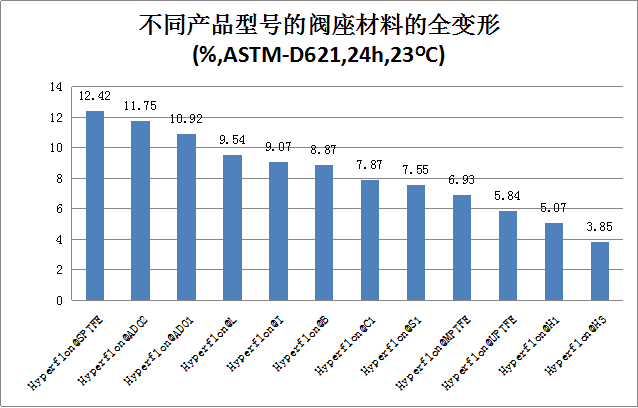

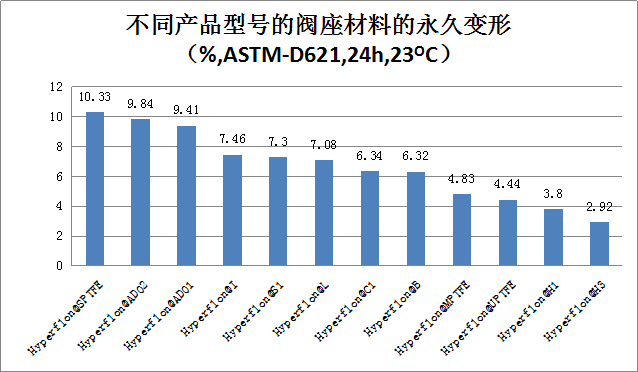

Valve seat series PTFE composite material - pressure resistance

Note: The above data in this manual are accurate and reliable, but it does not mean that Itaflon assumes any warranty or responsibility. This technical data sheet does not exempt customers from quality inspection of the suitability of this product through their own quality control procedures.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Jiashan Itaflon Fluoropolymer Technology Co., Ltd. No.8 Jiahe road,Jiashan county,Jiaxing city,Zhejiang province +86 0573 84892086 |

ITAFLON S.r.l. Via A. Volta, 18 24060 San Paolo D’Argon (BG) Italy +39 030 3663500 |

|

|

|

Related Applications

undefined