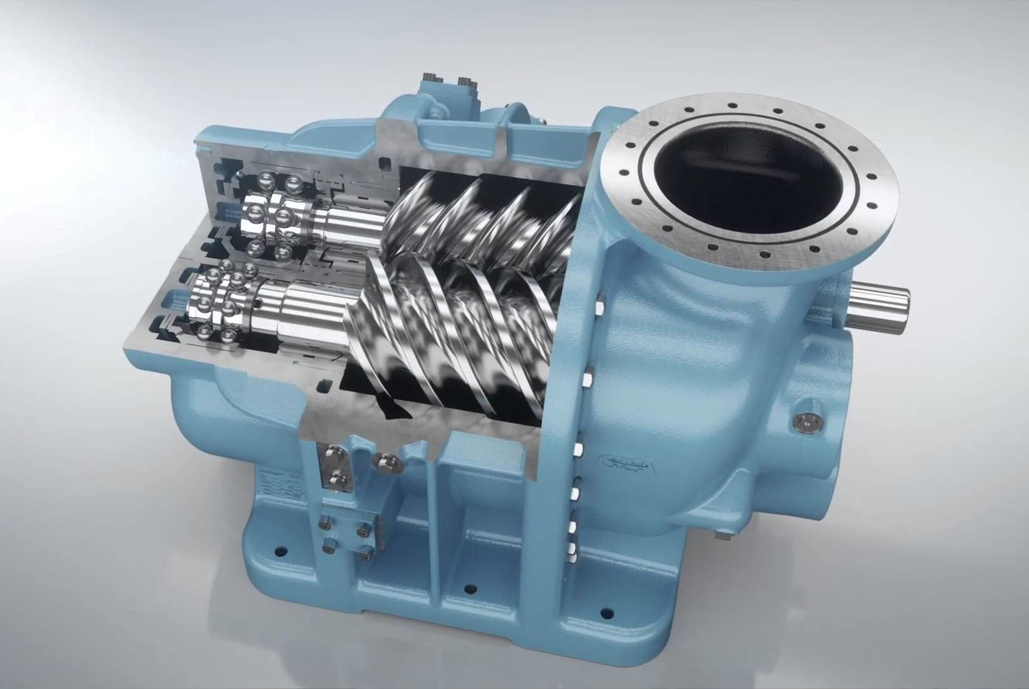

Oil-free compressor

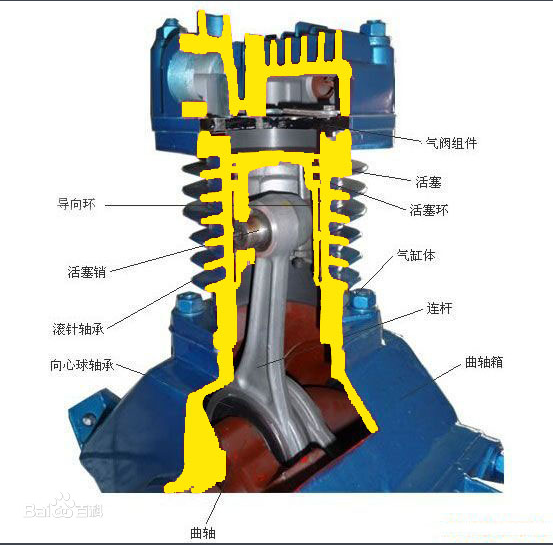

Oil-free compressor refers to the compressor without lubricating oil in the compressor cylinder. The crankcase of the completely oil-free compressor is of dry structure, and its connecting rod is large, small hole, and the main bearings before and after the crankshaft are generally made of fat ball bearings with double port seal. Because in operation, no lubricating oil and compressed gas source contact, so the exhaust gas does not contain oil and gas, so it is welcomed by users. But the grease sealed in the bearing will evaporate and decompose the grease due to the rising temperature in the long-term operation, and the thickener in the grease will deteriorate and lose the thickening effect. Due to the change of fat performance, the use effect decreases sharply, if the new oil is not added in time, it will directly damage the bearing and even the machine.

The advantages of oil air compressor are:

1. Because of the use of small cylinders, air compressors are light and compact in structure.

2. The balance of air compressor is good, so there is no need for foundation.

3. Slight vibration.

4. The small stroke volume of a single cylinder makes the pulsation of the intake end and the exhaust end less than 1%, so there is no need to install the pulsation elimination device.

5. The noise value is about 70-82 dB. No additional measures need to be taken.

6. Maintenance is simple. Because the air compressor components are small and light, the customer's own personnel can maintain the compressor.

7. Because the drive system is contact-free and maintenance-free, there is no need to use expensive piston rod stuffing box. The air compressor permanently maintains complete gas seal.

Suitable for formulation in oil-free compressors

Application Details

Oil-free compressor

Oil-free compressor refers to the compressor without lubricating oil in the compressor cylinder. The crankcase of the completely oil-free compressor is of dry structure, and its connecting rod is large, small hole, and the main bearings before and after the crankshaft are generally made of fat ball bearings with double port seal. Because in operation, no lubricating oil and compressed gas source contact, so the exhaust gas does not contain oil and gas, so it is welcomed by users. But the grease sealed in the bearing will evaporate and decompose the grease due to the rising temperature in the long-term operation, and the thickener in the grease will deteriorate and lose the thickening effect. Due to the change of fat performance, the use effect decreases sharply, if the new oil is not added in time, it will directly damage the bearing and even the machine.

The advantages of oil air compressor are:

1. Because of the use of small cylinders, air compressors are light and compact in structure.

2. The balance of air compressor is good, so there is no need for foundation.

3. Slight vibration.

4. The small stroke volume of a single cylinder makes the pulsation of the intake end and the exhaust end less than 1%, so there is no need to install the pulsation elimination device.

5. The noise value is about 70-82 dB. No additional measures need to be taken.

6. Maintenance is simple. Because the air compressor components are small and light, the customer's own personnel can maintain the compressor.

7. Because the drive system is contact-free and maintenance-free, there is no need to use expensive piston rod stuffing box. The air compressor permanently maintains complete gas seal.

Suitable for formulation in oil-free compressors

Related Applications

undefined